Flat, ribbed and toothed belts

General information

In the product group of flat, ribbed and toothed belts, there are power transmissions with a different design than V-belts. The flat belt is the "mother of all drive belts", originally made of leather, nowadays it is made of rubber and fabric. The advantage is that it turns well even on a relatively smaller pulley, the disadvantage is that it moves on the pulley and can easily slip off it... It can transmit less torque than V-belts, but it tolerates slipping well. Since it is not often used nowadays, it is relatively expensive. Ribbed belts combine the advantages of flat belts with the positive properties of V-belts. It's like tiny V-belts glued together...

General information

In the product group of flat, ribbed and toothed belts, there are power transmissions with a different design than V-belts. The flat belt is the "mother of all drive belts", originally made of leather, nowadays it is made of rubber and fabric. The advantage is that it turns well even on a relatively smaller pulley, the disadvantage is that it moves on the pulley and can easily slip off it... It can transmit less torque than V-belts, but it tolerates slipping well. Since it is not often used nowadays, it is relatively expensive. Ribbed belts combine the advantages of flat belts with the positive properties of V-belts. It's like tiny V-belts glued together...

They can also be used on small-diameter pulleys and can transmit large forces. It is often found as a drive belt for machines and equipment. Timing belts are a combination of V-belt drive and chain drive. It is not only friction that transfers the power, but also the transverse ribs located on the belt cling to the drive wheel, so it is able to transmit nearly the same driving forces as the V-belt drive in a smaller, much more compact design. Common in small electric machines.

Double-sided ribbed belts are mostly used in the food industry. Double toothed timing belts are toothed on both sides and can transmit drive on both sides. We use them when we want to drive one wheel in one direction and the other wheel in another direction... They are most often used on lawnmowers and milling machines. Running meter toothed belts are mostly used for linear movements, but the polyurethane versions can be made endless by baking, so they can also be used as drive belts. In the Special toothed belts group, you can find the toothed versions of Cable Pulling Belts, Foil Pulling Belts, and Mill Industry Grinding Roller Belts.

They can also be used on small-diameter pulleys and can transmit large forces. It is often found as a drive belt for machines and equipment. Timing belts are a combination of V-belt drive and chain drive. It is not only friction that transfers the power, but also the transverse ribs located on the belt cling to the drive wheel, so it is able to transmit nearly the same driving forces as the V-belt drive in a smaller, much more compact design. Common in small electric machines.

Double-sided ribbed belts are mostly used in the food industry. Double toothed timing belts are toothed on both sides and can transmit drive on both sides. We use them when we want to drive one wheel in one direction and the other wheel in another direction... They are most often used on lawnmowers and milling machines. Running meter toothed belts are mostly used for linear movements, but the polyurethane versions can be made endless by baking, so they can also be used as drive belts. In the Special toothed belts group, you can find the toothed versions of Cable Pulling Belts, Foil Pulling Belts, and Mill Industry Grinding Roller Belts.

News

Tot ce trebuie să știi despre bucșele conice (Taper Bushing)

În acest articol îți explicăm ce sunt bucșele conice, cum funcționează, unde se folosesc și de ce sunt atât de apreciate în agricultură și industrie.

next

Tot ce trebuie să știi despre bucșele conice (Taper Bushing)

În acest articol îți explicăm ce sunt bucșele conice, cum funcționează, unde se folosesc și de ce sunt atât de apreciate în agricultură și industrie.

next

Program de sărbători

🔒 24 – 28 decembrie: închis

✅ 29 – 30 decembrie: deschis

🔒 31 decembrie – 7 ianuarie: închis

next

Program de sărbători

🔒 24 – 28 decembrie: închis

✅ 29 – 30 decembrie: deschis

🔒 31 decembrie – 7 ianuarie: închis

next

Comunicat de presă

next

Comunicat de presă

next

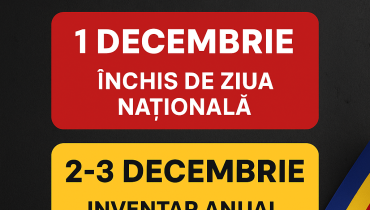

INVENTAR ANUAL

1 Decembrie - Ziua națională a României

2-3 Decembrie - inventar anual

⏰ În cazul comenzilor plasate în această perioadă, data preconizată de livrare va apărea incorect în mail-ul de confirmare trimisă automat despre comanda. (Termenul limită de livrare va fi amânat)

Mulțumim pentru înțelegere!

next

INVENTAR ANUAL

1 Decembrie - Ziua națională a României

2-3 Decembrie - inventar anual

⏰ În cazul comenzilor plasate în această perioadă, data preconizată de livrare va apărea incorect în mail-ul de confirmare trimisă automat despre comanda. (Termenul limită de livrare va fi amânat)

Mulțumim pentru înțelegere!

next